Research areas

Mission & values

Axis #1 | Continuous flow methodology

Continuous flow chemistry mostly relies on the inherent properties of the corresponding reactors that affect fluid dynamics, heat and mass transfers for streams of chemicals. It comes with a range of assets that can be advantageously exploited to improve chemistry in many instances: efficient mixing even with immiscible phases, efficient heat management, precise control over the residence time and local stoichiometry, inherent safety and potentially seamless scalability are amongst the most important. It also enables to explore new process windows, such as quick exposure to unconventionally high temperatures for organic reactions.

We develop technologies and methods under continuous flow conditions for:

- Enabling process conditions considered as demanding, hazardous or difficult to achieve in conventional batch setups

- Reactions involving rapidly decaying molecules, unstable and dangerous intermediates

- Complex sequences of reactions

- Improving process safety and efficiency

- Decreasing process space and time frames

Keywords : Electrophilic aminations, C-nitroso chemistry, Organophosphorus chemistry, Reactive gases, Unstable intermediates, Generators, Libraries

Axis #2 | Upgrading of bio-based platform molecules

The contribution of flow chemistry for designing safer and more reliable chemical processes using facilities with a low environmental footprint typically stimulates lots of hope in the scientific areas that addresses public needs for a greener, more sustainable and safer chemical industry. The various aspects of flow chemistry also contribute to the design of new strategies helping the transition from an exclusively petrobased to biobased industry, or at least to a more sustainable chemical industry, with applications ranging from commodity to specialty chemicals. The global downsizing of production facilities that comes with continuous flow processes positively impacts the global environmental footprint. Within this specific area of research, the lab develops integrated and scalable continuous flow strategies for the upgrading of biosourced platform molecules. Our research efforts aim at providing new strategies for improving the conversion of platforms toward industrially relevant building blocks or active pharmaceutical ingredients.

Keywords : Bio-based platforms, Glycerol, Furfural, Carbonation, Nitration, APIs

Axis #3 | Neutralization of chemical warfare agents

The aspects of downsizing, production intensification and relative affordability of the technology (DIY approach, 3D-printed reactors) might also contribute to boosting the illegal manufacturing of controlled substances, explosives or chemical warfare agents.

The lab develops integrated continuous flow strategies with minimal footprint for the preparation of psychotropic compounds and of simulants for chemical warfare agents, as well as integrated protocols for their chemical neutralization. Within the current context of increasing drug abuse and terrorism threats, our research efforts aim at providing reference compounds and protocols as well as safety procedures for the drug enforcement and military agencies. Please contact us directly for detailed information

Keywords : Bio-based platforms, Glycerol, Furfural, Carbonation, Nitration, APIs

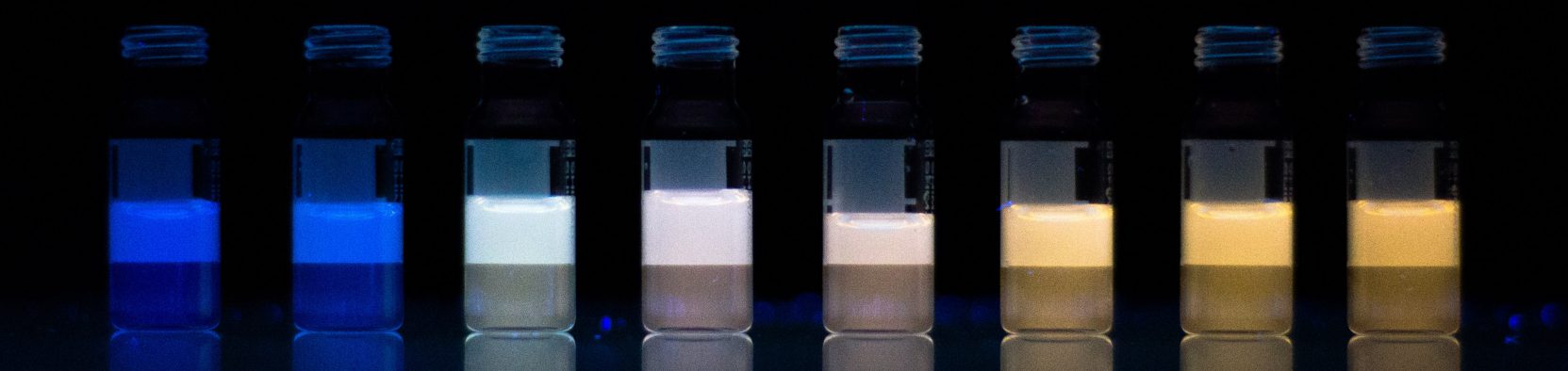

Axis #4 | Nanoparticles

We have started several research programs aiming at the tailored preparation of semi-conductor and noble metal nanoparticles under flow conditions. We have developed unique and scalable flow processes that will enable the industrial production of such high valued-added nanoparticles with low footprint setups. More details soon.

Keywords : Quantum Dots, NPs, Concatenation, Unstable precursors, Photochemistry

Axis #5 | Interface between Law and Organic Chemistry

Keywords : Dual Use, Schedule

I-III compounds, Psychotropic drugs, Specially regulated chemicals, REACH

Upon first glance, the study of law and organic chemistry might appear to be distant. However, it is crucial for scientists to cultivate a deeper understanding of the nexus between legal frameworks and organic chemistry. Many routine activities within laboratory settings, such as procurement, research conduct, and the sale or exportation of products, are subject to regulatory oversight and constraints. Navigating these legal complexities can be challenging, especially considering the significant differences between legislative and scientific literature and mindset. This research axis aims to facilitate the collaboration between laboratories and law enforcement agencies, both European and international, particularly concerning issues related to dual-use items and drug-related matters.

![[V5] Assets [V5] Assets](http://www.citos.uliege.be/wp-content/uploads/2018/03/V5-Assets.jpg)